Introduction

The packaging industry plays a crucial role in the global economy, with cardboard boxes being one of the most important elements in this sector. Corrugated cardboard is used to protect and transport products worldwide, and standardization in the design and production of these boxes is key to efficiency and quality. The FEFCO (European Federation of Corrugated Board Manufacturers) standard is one of the most important tools in this field. In this article, we will explore the FEFCO standard in detail, its history, categories, and its importance for manufacturers of box-making machines.

What is FEFCO?

FEFCO was established in 1952 as an organization representing the corrugated board industry in Europe. Their mission is to promote the use of corrugated cardboard through technical information, standards, and industry support. FEFCO provides guidelines and standards that help manufacturers maintain a high level of quality and efficiency in production.

FEFCO was established in 1952 as an organization representing the corrugated board industry in Europe. Their mission is to promote the use of corrugated cardboard through technical information, standards, and industry support. FEFCO provides guidelines and standards that help manufacturers maintain a high level of quality and efficiency in production.

FEFCO Standard

The FEFCO standard is an internationally recognized system for the classification of corrugated cardboard packaging designs. This standard was developed to facilitate communication and identification of different types of boxes worldwide, regardless of language barriers. Each design has a unique number, which makes identification and ordering simple.

Main Categories of the FEFCO Standard

The FEFCO code consists of several main categories that cover the most commonly used types of boxes. Here is an overview of the basic categories:

- Commercial Rolls and Sheets (0100): This category includes commercial rolls and sheets of corrugated cardboard.

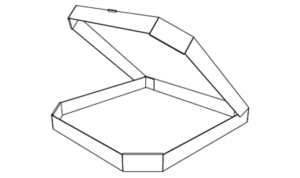

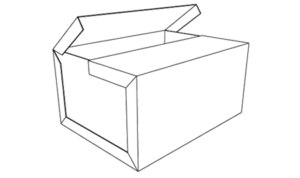

- Slotted Boxes (0200): Boxes with slots that consist of a single piece with glued, stitched, or taped joints.

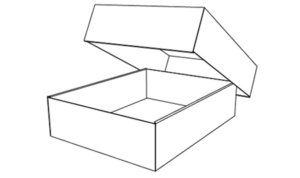

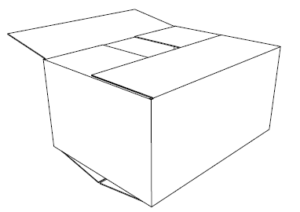

- Telescopic Boxes (0300): Boxes consisting of more than one piece (e.g., top and bottom) that overlap each other.

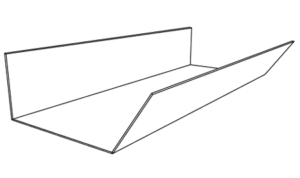

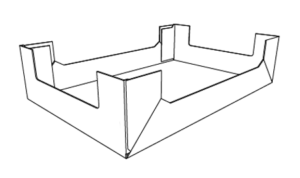

- Folder Boxes and Trays (0400): Boxes usually made from a single piece of board, with the bottom hinged to form the sides and cover.

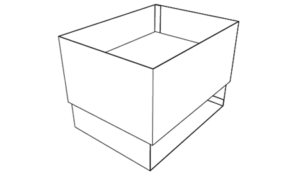

- Slide Boxes (0500): Boxes consisting of several pieces that slide into each other.

- Rigid Boxes (0600): Boxes made of two separate end pieces and a body that require stitching or a similar operation before use.

- Ready-Glued Cases (0700): Boxes ready for use by simple assembly.

- Retail and E-Commerce Packaging (0800): Packaging used for point-of-sale displays and e-commerce, including display boxes and trays.

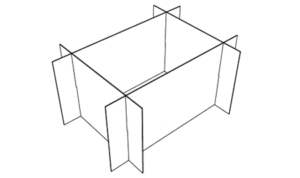

- Interior Fitments (0900): Internal parts such as liners, pads, partitions, dividers, etc.

Details of FEFCO Design

Each FEFCO design is precisely described with dimensions and specifications that facilitate production and usage. For example, a basic FEFCO code might look like this:

- 0201: Standard slotted box with glued or stitched joints and flaps.

- 0301: Telescopic box with two overlapping parts.

- 0401: Folder boxes and trays made from a single piece with hinged sides and cover.

Benefits of Using the FEFCO Standard

- Simple Communication: FEFCO codes enable simple and clear communication between manufacturers and customers, reducing the possibility of errors in orders.

- Standardization: Ensures consistency in the quality and design of boxes, which is crucial for large orders and global trade.

- Production Efficiency: Standardized designs allow manufacturers to optimize their production processes and reduce costs.

- Flexibility: The ability to customize and modify basic designs to meet specific customer needs.

Implementing the FEFCO Standard in Box-Making Machine Productio

For manufacturers of box-making machines, understanding and implementing the FEFCO standard is key to success. Machines must be designed to produce boxes according to these standards, which includes precise dimensions, joints, and functionalities.

For manufacturers of box-making machines, understanding and implementing the FEFCO standard is key to success. Machines must be designed to produce boxes according to these standards, which includes precise dimensions, joints, and functionalities.

Steps for Implementation

- Requirement Analysis: First, analyze the specific market and customer requirements. This includes identifying the most commonly used FEFCO designs in the industry.

- Machine Design: Machines should be designed to efficiently produce boxes according to the selected FEFCO codes. This may require modifying existing machines or developing new technologies.

- Testing and Verification: After designing, machines must be tested to ensure their ability to produce boxes according to FEFCO standards. This includes testing dimensions, joint strength, and overall product quality.

- Staff Training: Staff operating the machines must be trained to understand and use the FEFCO standards. This includes training on recognizing different codes, properly setting up machines, and quality control.

Practical Examples

- 0201 – Standard Slotted Box: This box is used for a wide range of products due to its simplicity and efficiency. Machines producing these boxes must be precisely calibrated for cutting, folding, and gluing.

- 0301 – Telescopic Box: Ideal for products requiring additional protection. Producing this box requires machines that can precisely produce parts that fit perfectly.

- 0401 – Folder Boxes and Trays: These boxes are popular for retail products and often include additional functionalities such as handles and windows for product display.

Technical Specifications

Each FEFCO design comes with technical specifications that include:

- Dimensions: All dimensions are expressed as internal dimensions in millimeters.

- Crease Lines: Precisely marked to ensure proper assembly of the box.

- Cut Lines: Define the contours of the box and ensure precise fitting of parts.

Conclusion

The FEFCO standard is an essential tool for everyone involved in the production and use of cardboard boxes. For machine manufacturers, this standard ensures that their machines can meet market demands and produce high-quality boxes in compliance with international standards. Understanding and implementing the FEFCO standard brings numerous benefits, including improved efficiency, cost reduction, and increased customer satisfaction. As industry leaders, it is important for manufacturers to stay informed about the latest developments and adapt their products and processes to remain competitive in the global market.